Search websites, locations, and people

ABOUT

ACADEMICS

RESEARCH

ADMISSIONS

NEWS & EVENTS

CAMPUS LIFE

INNOVATION

CAREERS

Spiders Inspire Artificial Muscle Production Breakthrough from Jiu-an Lv’s Lab

10, 2023

Email: zhangchi@westlake.edu.cn

Phone: +86-(0)571-86886861

Office of Public Affairs

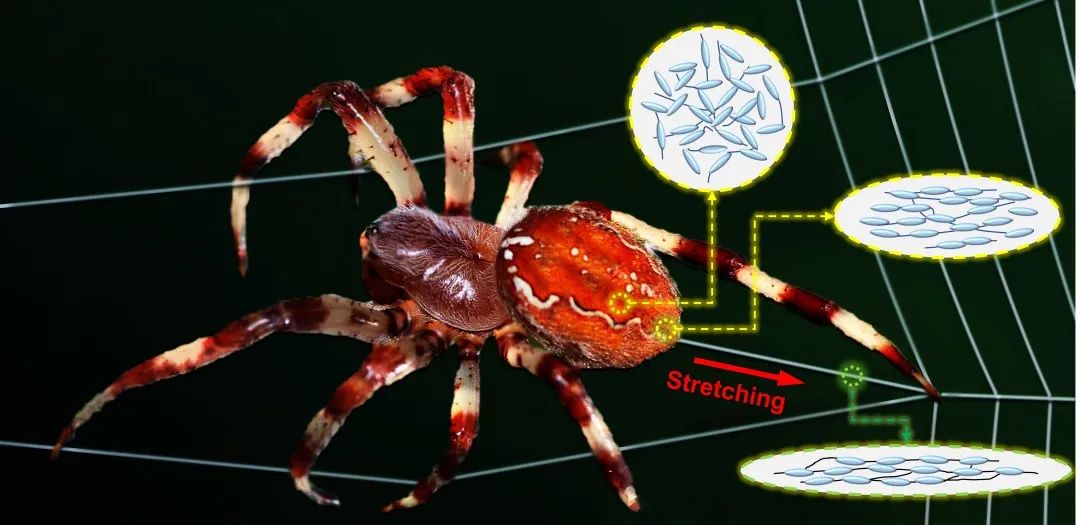

Biological principle of liquid crystalline spinning of spiders

Biological principle of liquid crystalline spinning of spiders

If you visited Jiu-an Lv’s lab, a miraculous scene would catch your eyes: raw materials poured into a homemade machine are being continuously and rapidly processed into long, thin, and mechanically robust fiber, and finally winded and collected onto spools.

Why did the smart polymer materials lab start to do the work of preparing fiber like a textile factory? Because this home-made machine is not a common fiber-spinning machine, while the fabricated fibers are also not traditional commercial fibers.

The raw material is liquid crystal elastomer, and the fiber it produces is liquid crystal elastic fiber. This can be used to make high-performing fibrous artificial muscles, which would benefit the development of smart fabrics, intelligent wearable devices, and humanoid robotics.

Why Employs Liquid Crystal Elastomers (LCEs)?

Liquid crystal (LC) is a special matter that possesses the combined properties of both conventional liquids and solid crystals, e.g., a liquid crystal material can behave like a liquid, but its molecules can be oriented in an ordered way like a crystal. These smart materials are composed of many rod-like molecules. Any change in the arrangement of liquid crystal molecules can exert a significant impact on the physical and chemical properties of the material.

Elastomers, such as rubber bands, are materials that can be restored to their original state after the removal of external forces. Elastomers are common soft materials widely used in our daily life, e.g., rubber bands that can return to their original shape after the external force is removed.

Liquid crystal elastomers are known for their flexibility, reversibility, strong response mechanical output, and programmable deformation. Back in 1975, the Nobel Prize in Physics winner Pierre-Gilles de Gennes declared that liquid crystal elastomers would be great for making artificial muscles.

But how do we process liquid crystal elastomers into High-Performing artificial muscle fibers?

Over the past two decades, the scientific world explored melt stretching, microfluidics, direct writing 3D printing, and electrospinning, none of which managed to produce high-performing fibrous artificial muscles continuously or efficiently. Therefore, turning liquid crystal elastomers into fibrous artificial muscles has remained a laboratory experiment instead of a commercial reality.

Getting inspiration from spiders

There are two technical challenges in the processing of fibrous liquid crystal elastomers: fiber formation and liquid crystal alignment. Conventionally, researchers would produce one short fiber and stretch it – this way, the mechanical stretch could induce the orderly arrangement of mesogens in fibers. Liquid crystal alignment is crucial to the excitation performance of fibrous liquid crystal elastomers, and highly ordered liquid crystal alignment is helpful for obtaining high-performance artificial muscle fibers.

But the conventional method is slow, inefficient, and not scalable. However, traditional processing technologies are not only low-efficient and discontinuous in the fabrication, but also unable to achieve high comprehensive actuation performances of the prepared fiber.

Inspiration often lies within our arm’s reach, and this time, the answer came from spiders. Spiders capable of the production of tough and strong dragline silks are nature's spinning masters specializing in the preparation of high-performing microfibers.

Spiders secrete from their abdomen a dope made of liquid crystals. The liquid crystal dope flows through a funnel-shaped channel before reaching the spinneret at the rear of the abdomen. In this process, the dopel is stretched and thinned by the channel and the liquid crystals inside are also shaped and aligned by the tapered-wall-induced-shearing. When spiders are spinning the dope from their spinnerets, the external drawdownvia mechanical stretching exerted by their legs shapes the spun fiber into long, thin, and aligned microfiber with high strength and toughness a

From liquid crystal dope to high-performing fibers, a straightforward and versatile approach for preparing high-performing fibrous liquid crystal elastomers.

Thanks to this inspiration, Lv’s team conceived of a new method that could continuously and efficiently produce fibrous liquid crystal elastomers. Inspired by the biological principle of liquid crystalline spinning of spiders, Lv’s team created an advanced technology that enables continuous and high-speed fabrication of high-performing LCE microfibers.

Artificial Muscle microfibers of different diameters created by Lv’s team

Artificial Muscle microfibers of different diameters created by Lv’s team

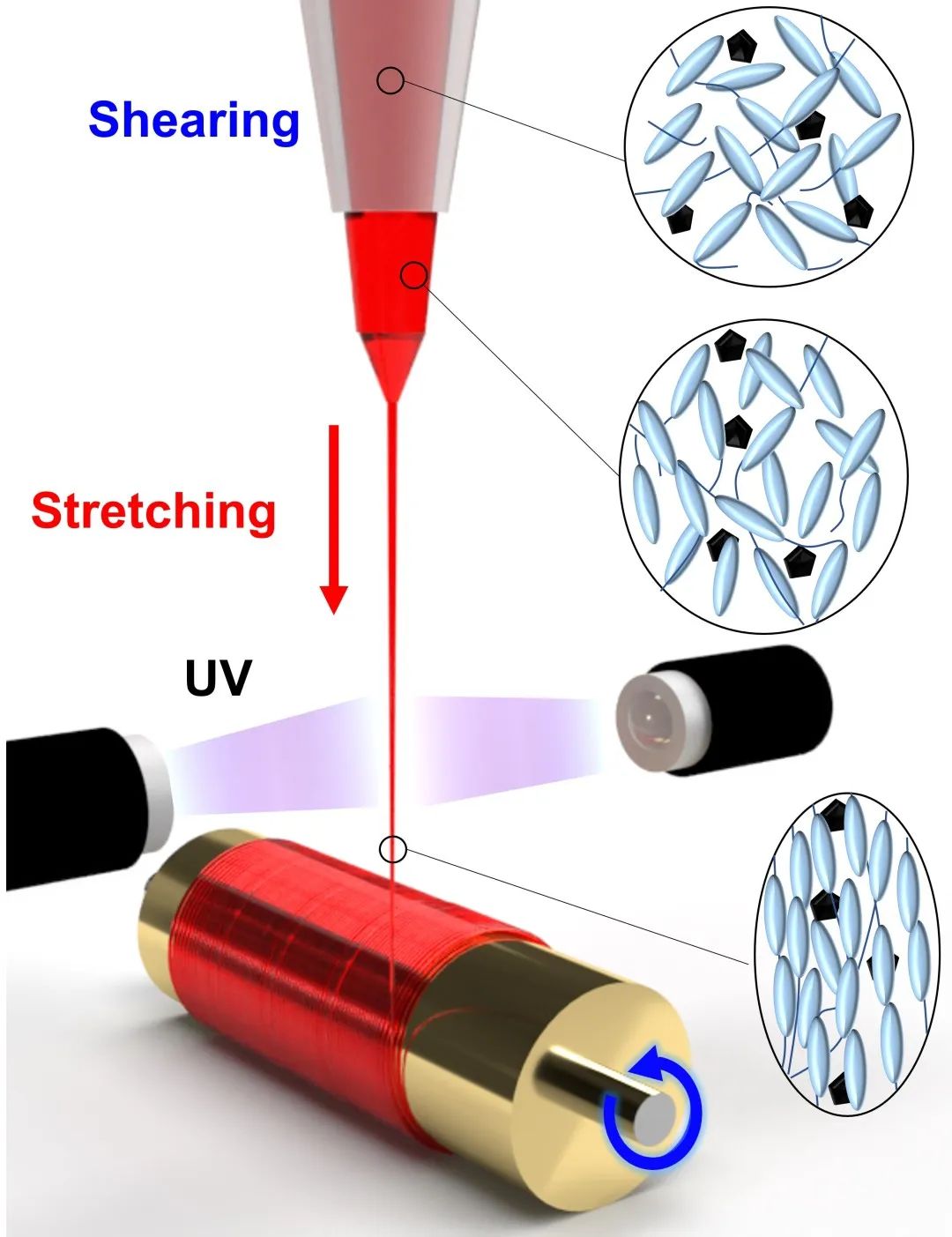

They designed a funnel-shaped secreting mechanism like the one inside a spider. Once fibrous liquid crystal elastomers were extruded, the roller performed multiple drawdowns to thin the dragline silks, similar to what spiders do.

The funnel-shaped extrusion device is designed to mimic the feature of the flow channels of spiders. The extruded LCE fibers are thinned through mechanical stretching via the rolling roller, which is similar to the thinning and alignment effect employed by the stretching of spiders using their legs.

Schematic diagram of high-speed and continuous liquid crystalline spinning

Schematic diagram of high-speed and continuous liquid crystalline spinning

The mechanical stretching then helped to transform liquid crystal elastomers into long, thin, and aligned microfibers which also have a desirable actuation performance.

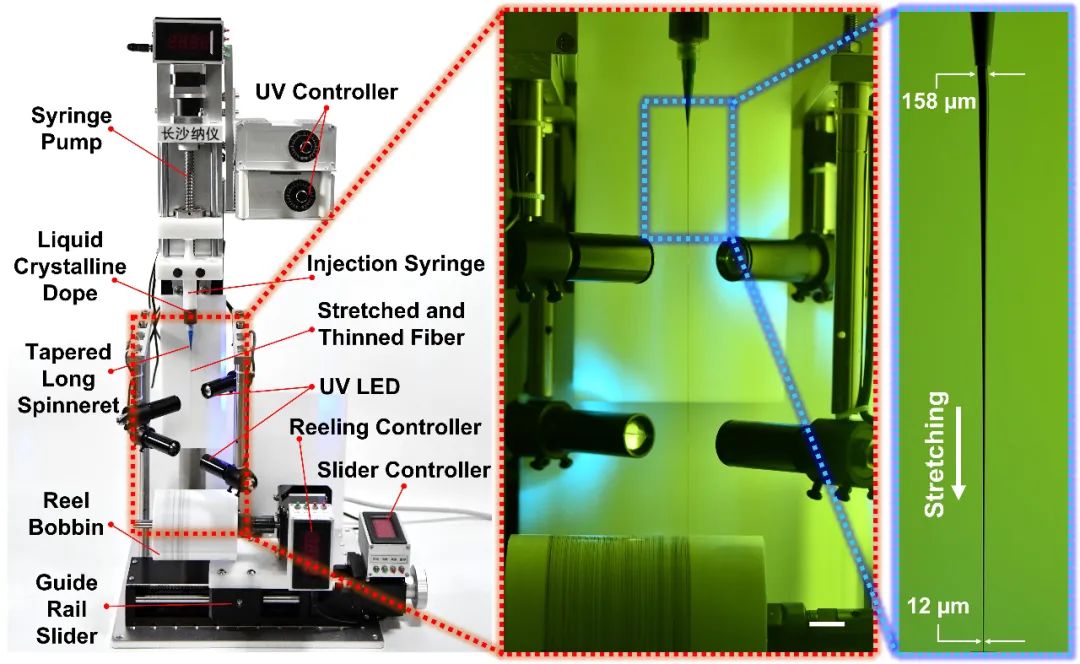

The processing technology is highly efficient (Lv’s team could reach a fabrication speed of 8,400 meters per hour, far greater than the highest recorded speed of around 5,000 meters per hour), and it doesn’t need to use high temperatures or pressure or toxic chemicals in the fabrication process.

high-speed and continuous spinning equipment and its partially enlarged photograph. the and the spinning process

high-speed and continuous spinning equipment and its partially enlarged photograph. the and the spinning process

The future of artificial muscles

Artificial muscles, despite the name, are not designed to look artificial, as researchers aim to develop something that functions just like real muscles. Instead, the goal is to develop their function as close as possible to real muscles, making LCE microfibers serve alone or in multiples to offer muscle-like functionalities.

Wenhao Hou, a Ph.D. student of the Smart Polymer Materials Lab, demonstrated the broad application prospects of high-performing liquid crystal elastomer microfiber in engineering fields. The microfiber contracts axially when irradiated with light and can pull a load 2,000 times its own weight. Therefore, artificial muscles can mimic many human muscle functions. For example, Hou combined multiple fibers together to mimic the actions of chewing and biting food, just like human masseter movement. He then used microfiber bundles to generate the muscle contraction function, mimicking the actions of the biceps lifting heavy objects. Hou also utilized microfiber bundles to create artificial quadriceps that can exert kicking action.

Liquid crystal elastomer microfibers work as artificial masseters, artificial biceps and artificial quadriceps to drive multiple biomimetic movements.

Liquid crystal elastomer microfibers work as artificial masseters, artificial biceps and artificial quadriceps to drive multiple biomimetic movements.

The liquid crystal elastomers actuation strain and stress of LCE microfibers can be regulated by light intensity, which makes liquid crystal elastomer microfiber viable as the driver of micromechanical devices. For example, it delivers a shutter speed of 0.48 seconds for a micro tweezer of 3.2 millimeters controlled by near-infrared light. Lv’s team also successfully mimic the flapping of dragonfly wings. The bionic wings made of liquid crystal elastomer micofibers can achieve fast flapping at a frequency of up to 10 hertz, which is close to the natural frequency of dragonfly wing movement (8-15 hertz).

Artificial muscles can also be used for smart fabrics, intelligent wearable devices, humanoid robotics, and more. We could weave the liquid crystal elastomer microfibers into smart clothes the way we weave sweaters. People with injuries could manipulate objects with the help of light or heat activation. VR could enhance the real experience of games.

As many more fascinating experiments continue in Lv’s lab, we look forward to seeing how the eventual commercialization of these cutting-edge materials will change our lives.

RELATED

ACADEMICS

Researchers Discovered A New Nucleation and Crystallization Strategy for Perovskite Solar Cells

ACADEMICS

Spiders Inspire Artificial Muscle Production Breakthrough from Jiu-an Lv’s Lab